Best Practices for a Portable Cutting Torch

Image via DALL-E

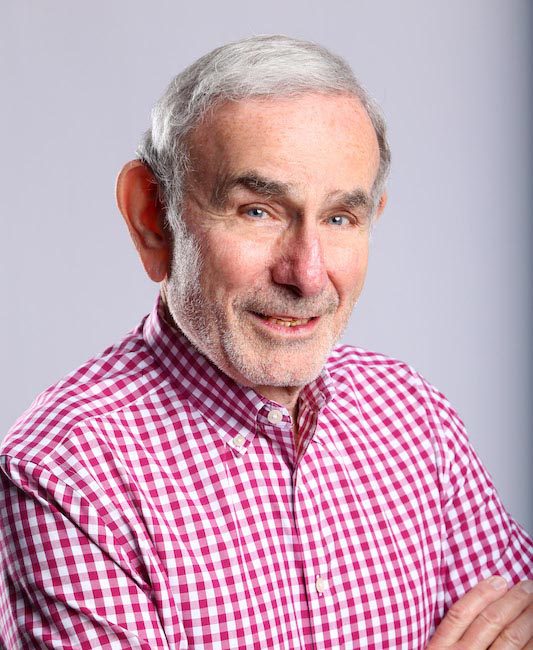

Mastering a portable cutting torch can significantly improve the efficiency and quality of your welding projects. Whether cutting through thick metal or making precise adjustments, following the correct practices will help you get optimal results while staying safe. This guide covers best practices for a portable cutting torch.

Choosing the Right Torch

Selecting the best portable cutting torch depends on several important factors. Start by identifying the fuel type you’ll use—typically oxygen with acetylene or propane. Assess the torch’s cutting capacity to match the thickness of the materials you’ll work with.

Lastly, consider its portability, especially if moving frequently between job sites. To save time and boost efficiency, your welding shop needs a motorized portable cutting torch, as it can tackle complex projects with ease and precision.

Safety First

Safety is paramount when working with a portable cutting torch. Always work in a well-ventilated area to prevent the buildup of harmful gases. Personal protective equipment, such as safety goggles, gloves, and flame-resistant clothing, is essential for protecting yourself from sparks and heat. Keep a fire extinguisher within easy reach to handle emergencies.

Setting Up Your Workspace

Preparing the workspace plays a critical role in cutting torch operations. Secure the workpiece firmly in place to prevent movement. Remove any flammable materials from the area to reduce fire risks. Use a sturdy, stable platform to keep the torch and the workpiece at the proper angle, creating a safe and efficient environment for cutting.

Operating the Torch

Follow these steps to operate a portable cutting torch effectively. Begin by inspecting the torch for any issues, such as loose connections or damaged hoses. Ignite the torch using a striker, not a lighter. Adjust the flame until you achieve your material’s size and intensity. Steady movements guide the torch, maintaining control and precision throughout the cut.

Maintenance and Storage

Proper maintenance extends the lifespan of your portable cutting torch. Clean the torch after each use to prevent carbon buildup and residue from clogging the nozzles. Regular inspections are vital to identify worn components that require replacement. Keep the torch in a cool, dry place away from flammable materials, and always disconnect the fuel lines to prevent leaks.

Troubleshooting

Like any tool, portable cutting torches can have issues. Uneven cuts often result from incorrect flame settings or worn nozzles, which can be fixed through timely adjustments or part replacements. Poor ignition might be due to clogged tips or low gas pressure. Fuel leaks are a serious concern and should be addressed immediately by checking and tightening all connections or replacing damaged parts.

When used correctly, a portable cutting torch is a powerful asset. By following the above best practices, you can elevate the quality and efficiency of your work. For welders handling diverse projects, a motorized portable cutting torch is an invaluable addition to any shop. Start enhancing your welding operations by taking these essential steps today.

Originally Published on https://www.breakfastleadership.com/