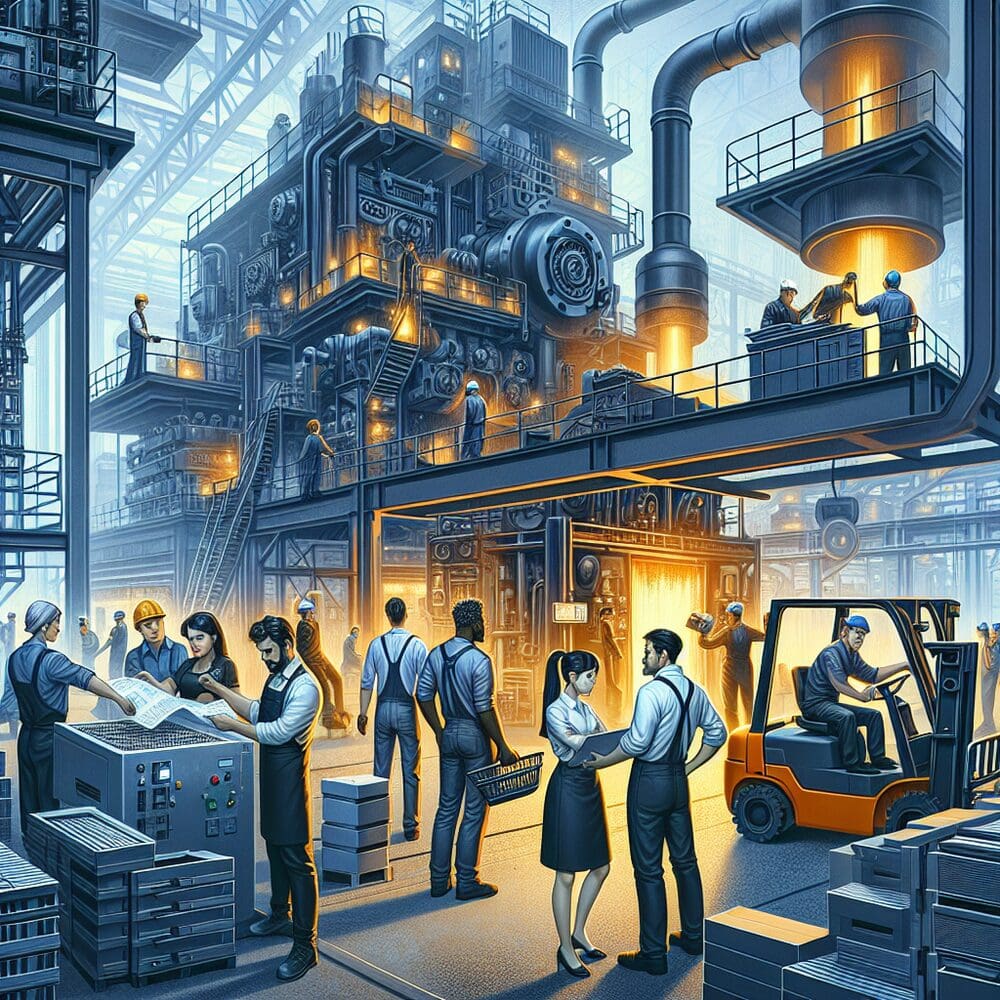

How You Can Make Sure Your Heavy Industry and Manufacturing Runs Smoothly

Image via DALL-E

The manufacturing industry is massive, and heavy industry can be challenging to manage. Any degree of heavy industry requires a heavy level of financial investment, and a lot can go wrong.

Ideally, your industry will be productive and efficient. Waste is your enemy, as time and Money can drain away. So, with this in mind, here are a few ways to ensure that everything runs as smoothly and productively as possible.

The Right Equipment

It’s a simple fact that you can’t run a factory without any equipment or tools. But finding the right equipment for the job isn’t an easy task. It requires research and a good knowledge of your trade.

Most heavy machinery and equipment come at a very hefty price. Some manufacturers prefer hiring machinery as and when needed rather than buying it. This has some pros and cons.

Hiring is helpful if you don’t use something often, as it has less short-term costs. But if you use something a lot, it is more expensive. Also, when you hire equipment, you don’t have it on-site. This reduces the need to store equipment, but it does mean it’s less convenient.

Typically, it’s best to buy equipment that you use frequently and hire things you only need for certain projects. This reduces costs as much as possible.

You also need to ensure that the equipment is well-maintained and fit for the job. Turbines that generate energy need to be in great condition so they can keep running, so always be ready to repair and replace parts and equipment when necessary.

Trained Employees

On a similar note, a factory is about as productive as its least productive worker. Employees keep everything running, and even in an increasingly automated world, we need people to ensure that things don’t break down.

However, the most important thing is that your employees are trained and qualified. Heavy machinery and equipment often need a skilled operator. Otherwise, they risk breaking the machine and causing significant damage.

Could you make sure you know what qualifications you need when hiring someone for a specific role?

Implementing an in-house training program can also be helpful. This way, you can train more employees and help apprentices and less experienced workers move up the ranks. You can get more out of your employees this way, and you can help them advance their careers.

Logistics and Fleet Management

Logistics is one of the most important things to consider when trying to make your company more efficient and productive. Often, if there’s a bottleneck or a shortage, it’s a logistics problem. This causes time and money to go down the drain.

Unfortunately, logistics is a massively complicated business in its own right. Hiring a logistics company is the most efficient way to keep things running well. Yes, outsourcing comes with an extra cost, but it means things are likely to go right.

If you have a fleet of vehicles, look for ways to cheaply maintain and improve the fleet to keep it running well. Broken-down vehicles are yet another drain on your wallet, so it’s better to be proactive with maintenance rather than waiting for problems to arise.

Warehouses can be a great way to reduce bottlenecks and shortages and break up long journeys so it’s easier to supply your factories and customers. However, please avoid stockpiling too much. It’s often better to have a lighter and more flexible storage and logistics system rather than a mass of items gathering dust and wasting money.

When finding vendors and other suppliers, think about the cost of transportation and the price of the product and materials. Yes, you might be able to get materials cheaper from the other side of the world, but shipping costs and potential complications can massively bump the price up.

AI logistics tools can find potential issues in a supply chain and make it simpler and more efficient. This means that your supply chain is also more reliable and resistant to possible problems that might crop up. You can’t plan for everything, but you can be prepared to react quickly.

Safety First

Heavy industry is one of the most dangerous industries in the world. The machinery involved can injure or kill a person very quickly if misused, which is why it’s so important to make sure that your employees are adequately trained and qualified. Be aware of potential hazards.

It would be best if you also implemented safety guidelines. While this might sometimes seem slower and more efficient, accidents can cause production to halt completely. Depending on what happens, your company might be shut down for a while.

Research the local guidelines and go the extra mile. Provide PPE for your employees and ensure a safety officer and first aider is always on site. This way, minor injuries can be treated immediately, and significant injuries can be stabilized when emergency services arrive.

It would be best to have emergency procedures for fire and other potential disasters so that employees know where to go and what to do.

Finally, could you ensure your company has insurance to deal with accidents? Sometimes, things happen no matter what you do, but at least you’re legally and financially covered.

Reducing Waste

Reduce material and energy waste whenever possible. While some machines can’t be powered down, turn off what you can when it isn’t in use.

When using materials, try to reuse as much as possible and avoid wasting too much. This might mean working more slowly to make efficient use of your resources.

This kind of waste reduction is sound financially and can be beneficial to the environment. In turn, it can lead to potential government rewards and improved public opinion.

Subscribe to our newsletter and Explore insightful conversations on workplace culture, Burnout, and leadership at the Breakfast Leadership Network, ranked Top 20 globally. Join us to thrive in the modern work environment.

Please stay connected with us! For more insights and valuable content, don’t forget to check out the following resources:

– **Breakfast Leadership Show Podcast**: Tune in to our podcast and get inspired by leadership lessons and success stories from top industry leaders.

– **Breakfast Leadership YouTube Channel**: Subscribe to our YouTube channel for video content on leadership, Personal Development, and more.

– **Hire Michael D. Levitt to Speak**: Looking for a dynamic speaker for your next event? Hire Michael D. Levitt, the founder of Breakfast Leadership, to share his expertise and insights.

Follow us on LinkedIn for the latest updates. Remember to share this article with your network!

Originally Published on https://www.breakfastleadership.com/